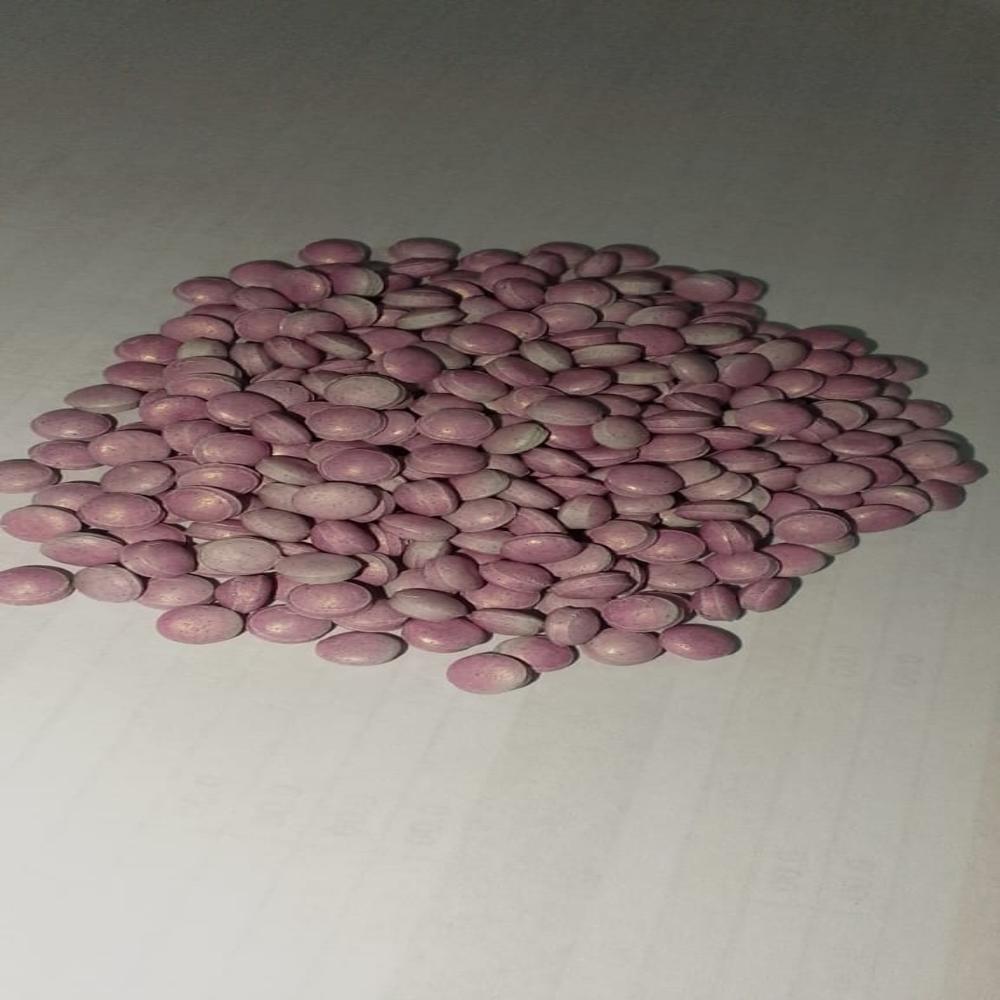

Pink Granules

Product Details:

Pink Granules Price And Quantity

- 65.0 INR/Ton

- 50 Ton

Product Description

Reprocessed LD Colour(Low-Density Polyethylene) granules are made from recycled LDPE material. These granules are created by reprocessing used or waste LDPE products, which involves several steps to prepare the material for reuse. Heres an overview of the process and considerations:

Process for Creating Reprocessed LD Colour Granules:-

Collection: Gather used or scrap LDPE materials, such as films, bags, or containers.

-

Sorting: Separate the LDPE materials from other types of plastics and contaminants.

-

Cleaning: Remove any impurities, labels, and residues from the collected materials to ensure a clean feedstock.

-

Shredding: Cut the cleaned LDPE into smaller pieces or flakes to facilitate further processing.

-

Pelletizing: Melt the shredded LDPE and extrude it into granules or pellets. This step often involves heating and mixing the material to achieve a uniform consistency.

-

Cooling: Allow the melted material to cool and solidify into pellet form.

-

Quality Control: Inspect the reprocessed granules for consistency, size, and contamination to ensure they meet the required specifications.

- Manufacturing: Used in the production of new LDPE products, such as films, bags, and containers.

- Blending: Can be mixed with virgin LDPE or other materials for specific applications.

- Construction: Sometimes used in construction materials, such as composite panels or insulation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+